1. What is JENOLITE Bitumen Undercoat Anti-Corrosion Spray Paint used for?

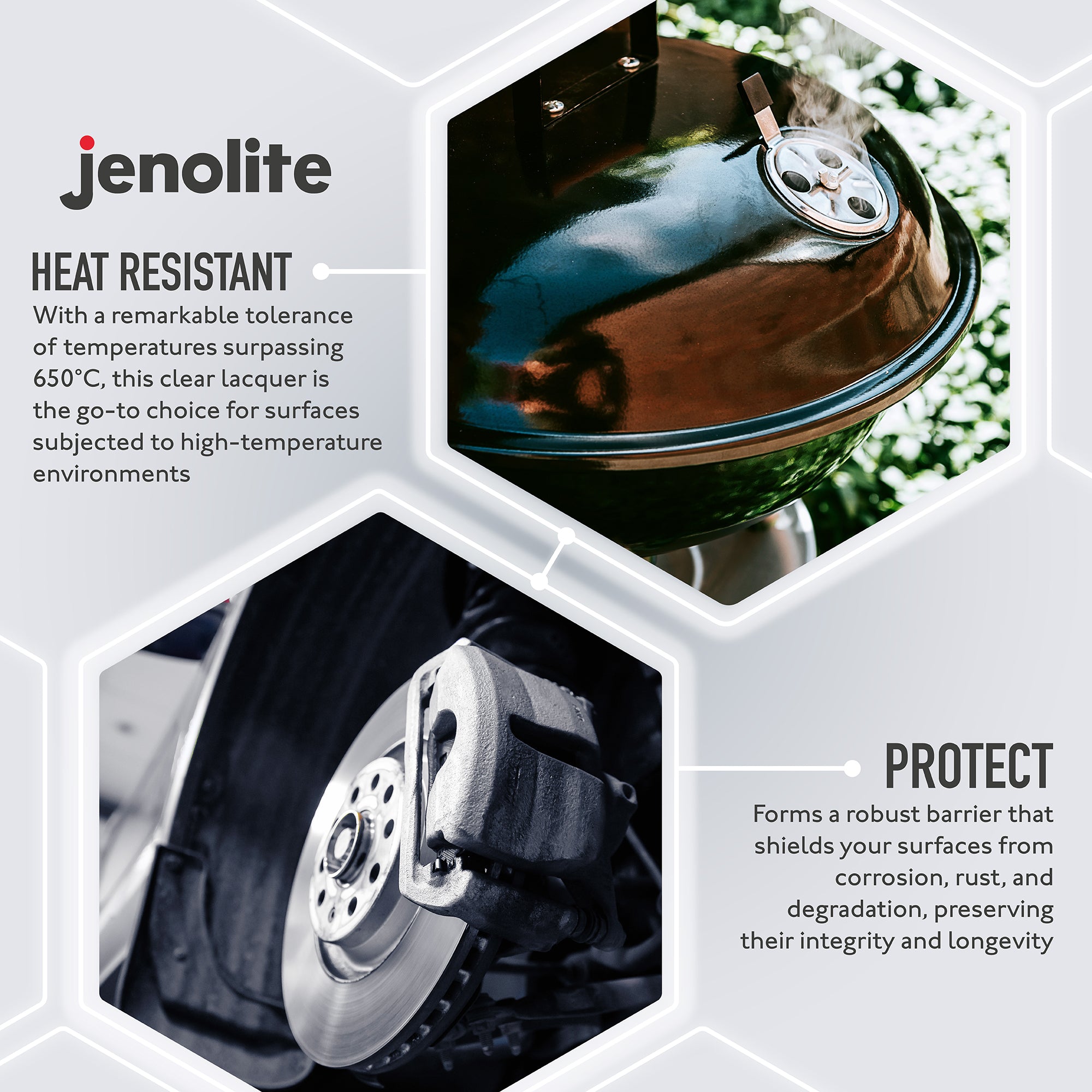

This bitumen-based undercoat spray is designed to protect vehicle underbodies, chassis, wheel arches, and other hard-to-reach areas from rust, corrosion, and damage caused by road debris, moisture, and salt. It can also be used for seal-leaking gutters and patch roofs.

2. What surfaces is it suitable for?

- Car underbodies, chassis, wheel arches

- Trucks, trailers, and industrial vehicles

- Metal surfaces exposed to vibration, impact, and moisture

- Gutters and roof patches

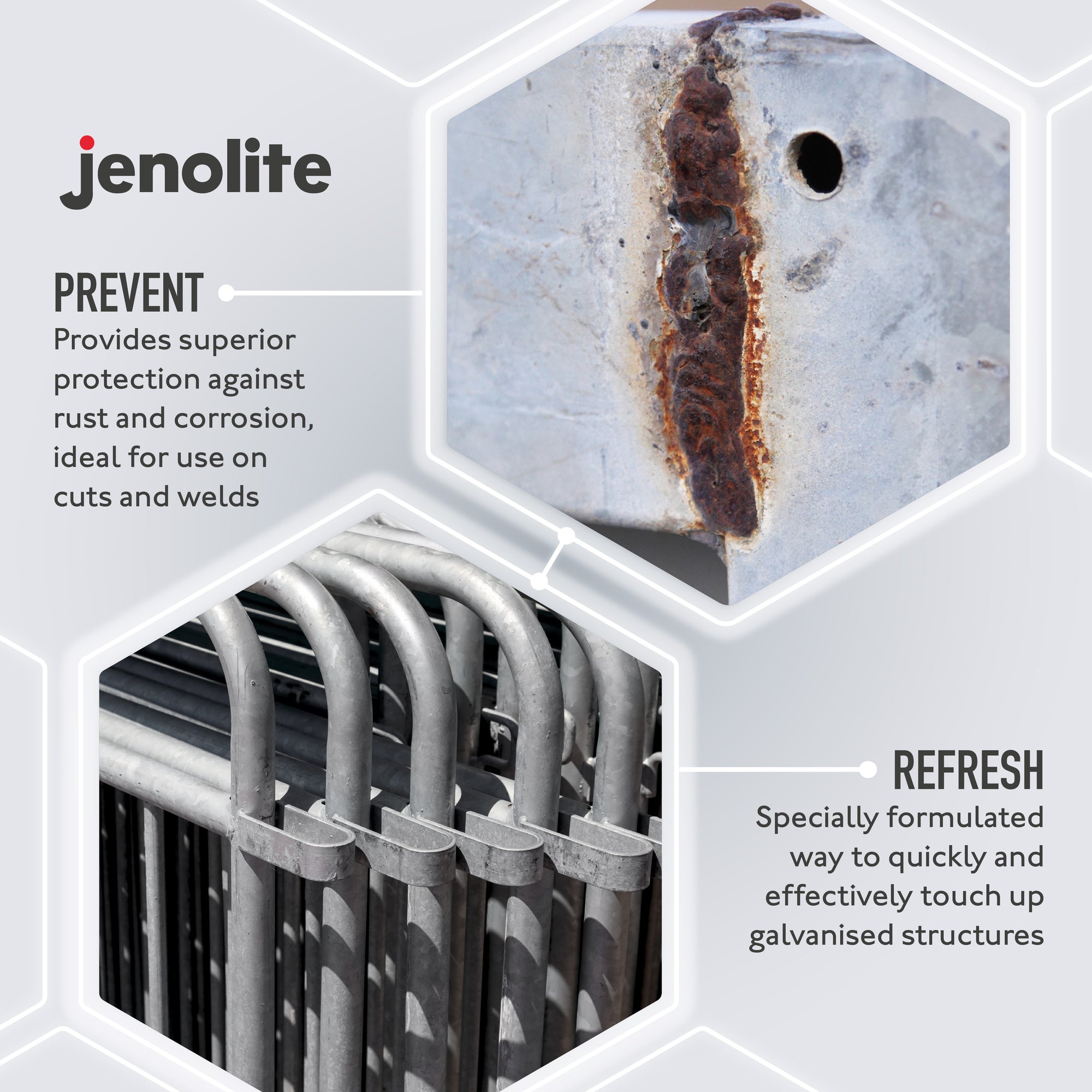

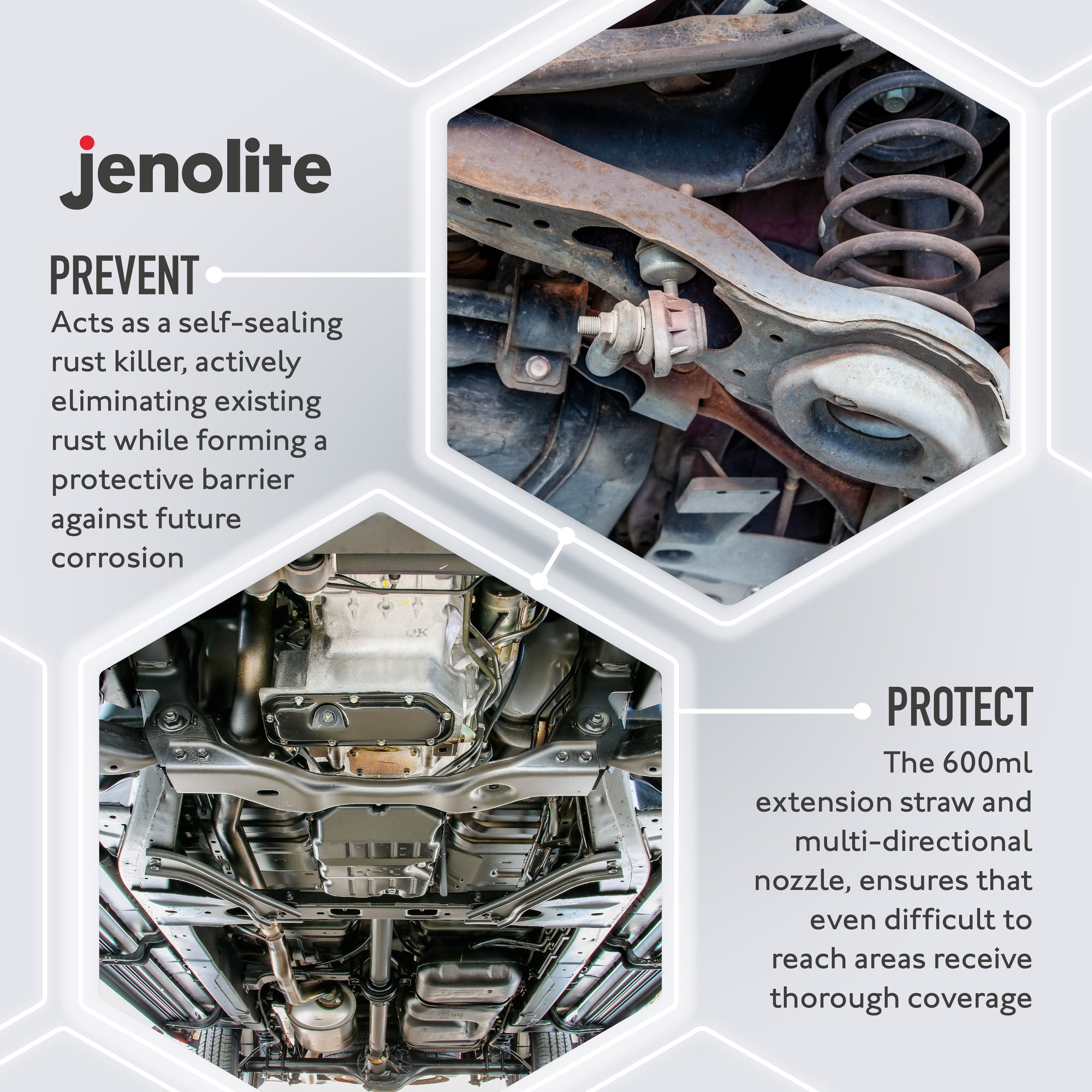

3. How does it protect against rust?

The flexible, weatherproof coating forms a durable barrier that prevents water, salt, and road debris from reaching metal surfaces, effectively stopping corrosion and rust before it starts.

4. What finish does it provide?

A black, flexible bitumen coating that adheres strongly to metal surfaces, providing a protective and impact-resistant underseal finish.

5. Can it withstand harsh conditions?

Yes. The coating is resistant to temperature changes, impacts, vibrations, and moisture, making it ideal for vehicles exposed to all-weather driving conditions.

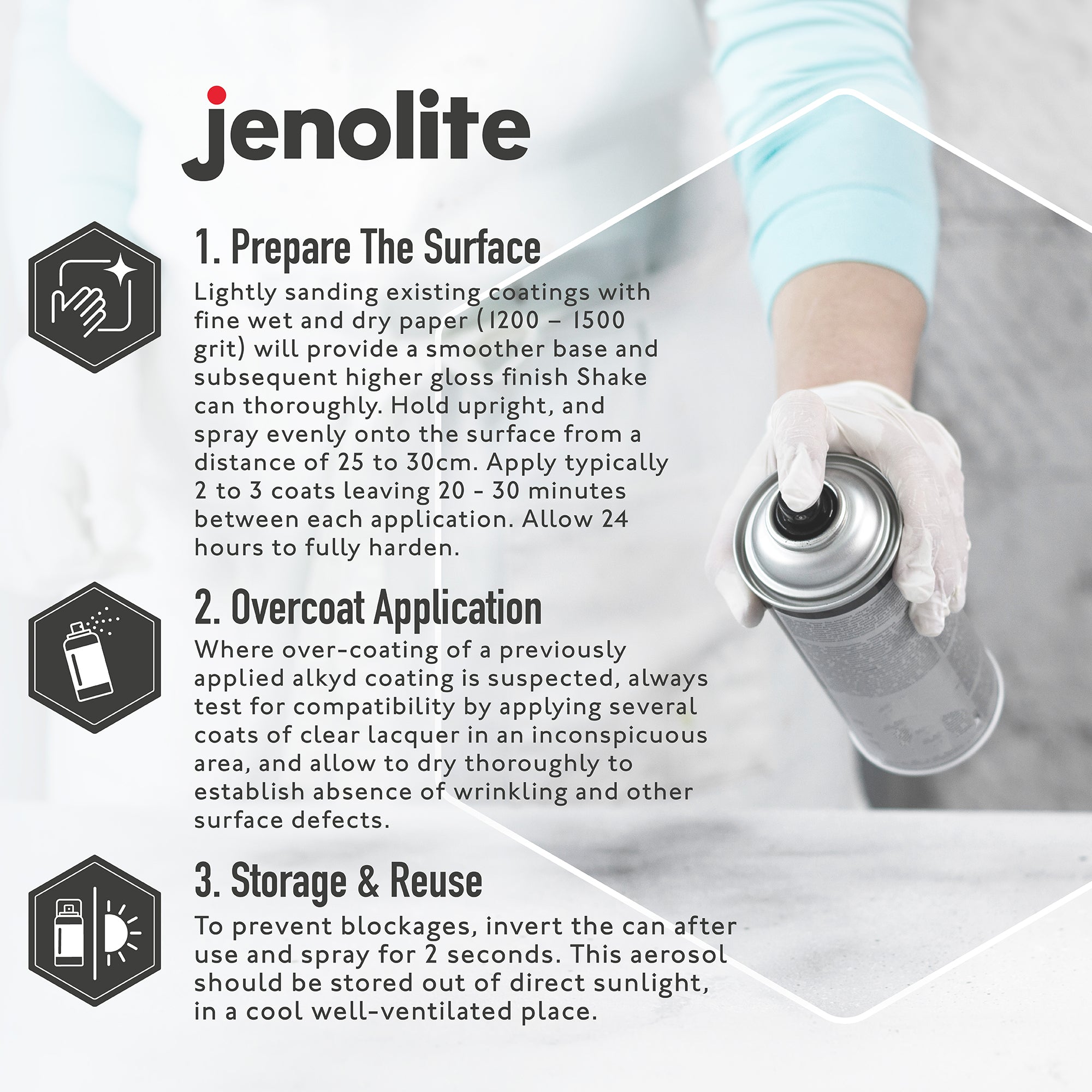

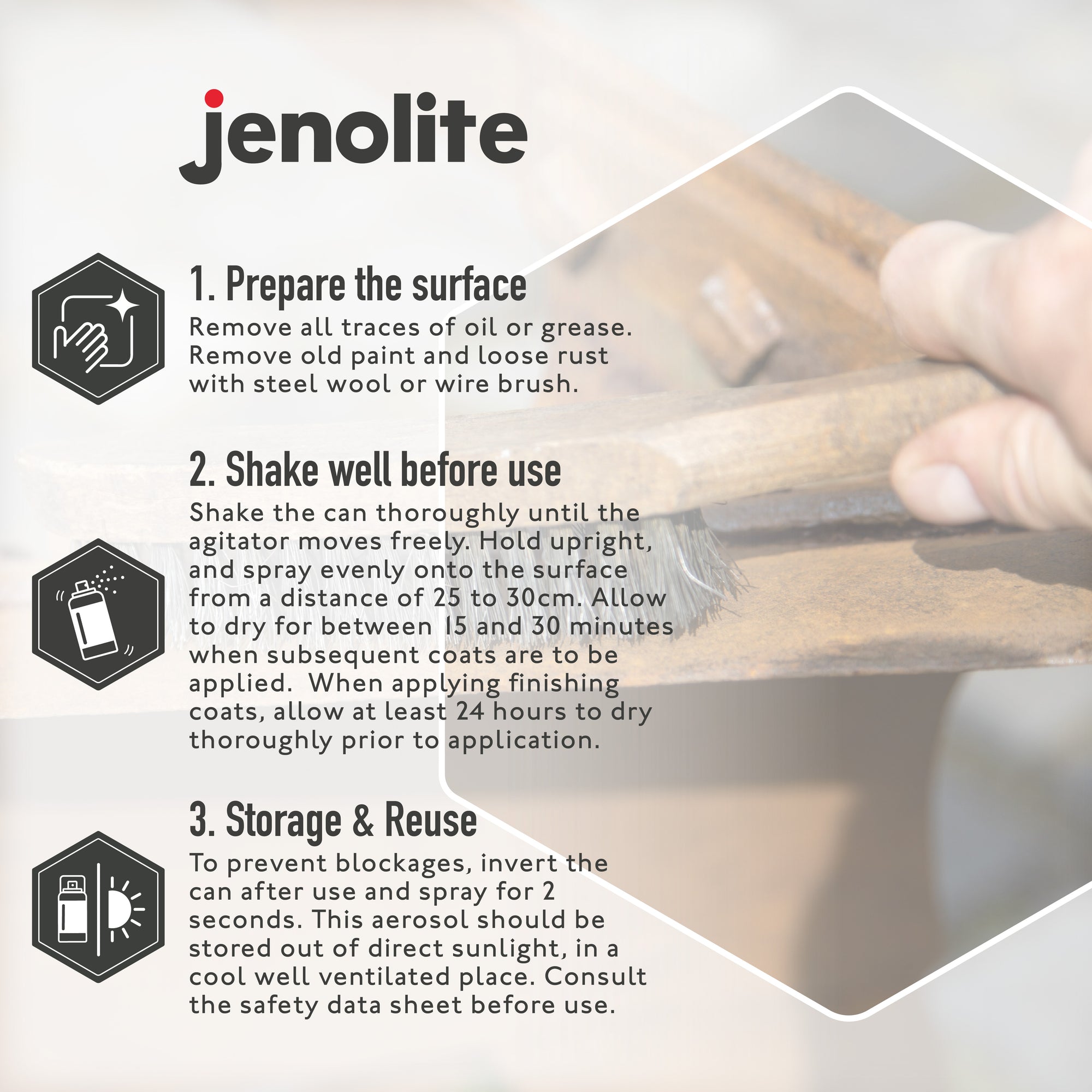

6. How do I prepare the surface?

- Remove all loose dirt, oil, grease, and rust using a wire brush, steel wool, or abrasive paper.

- Ensure the surface is clean and dry before application.

- For maximum protection, treat bare metal with an anti-corrosion primer prior to using the bitumen undercoat.

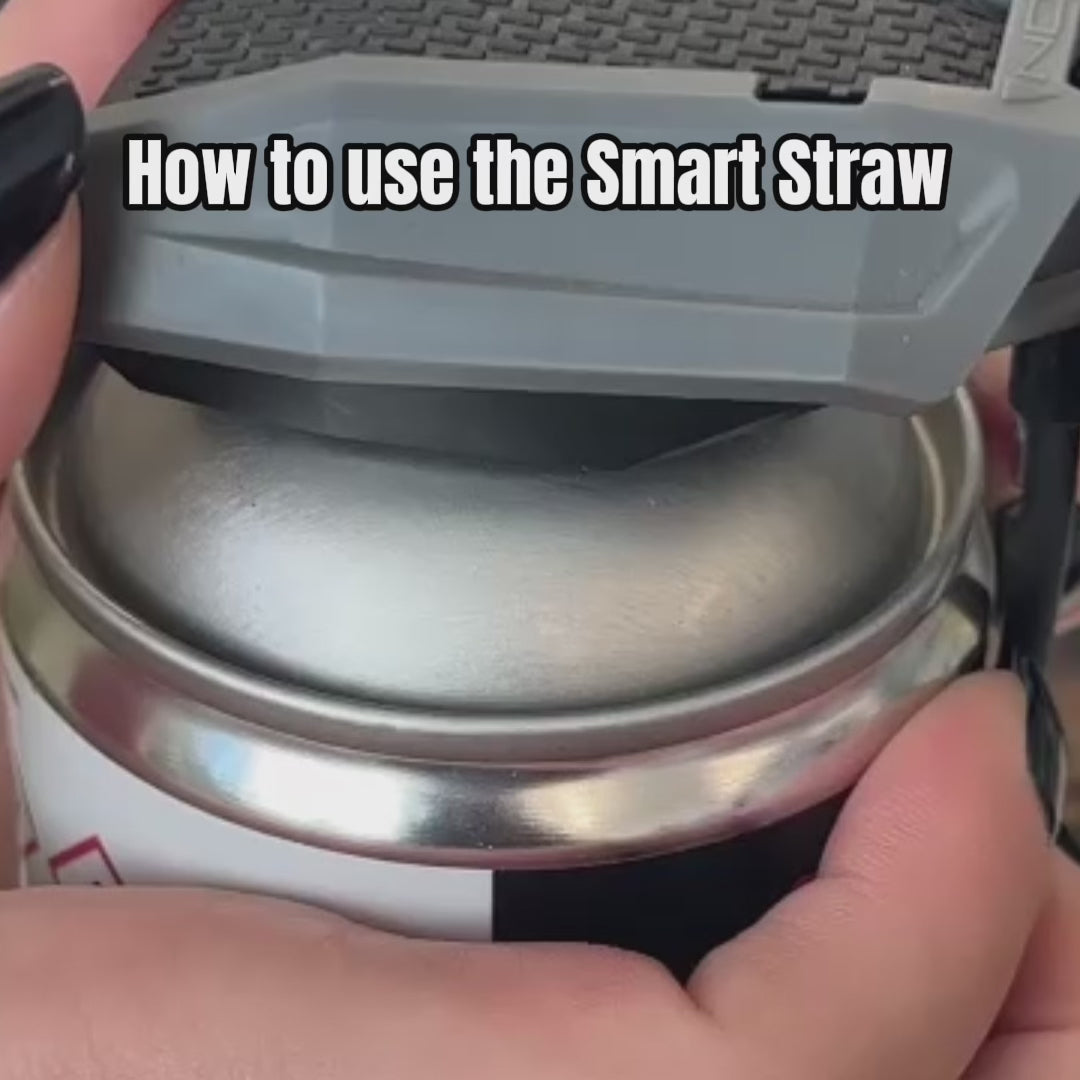

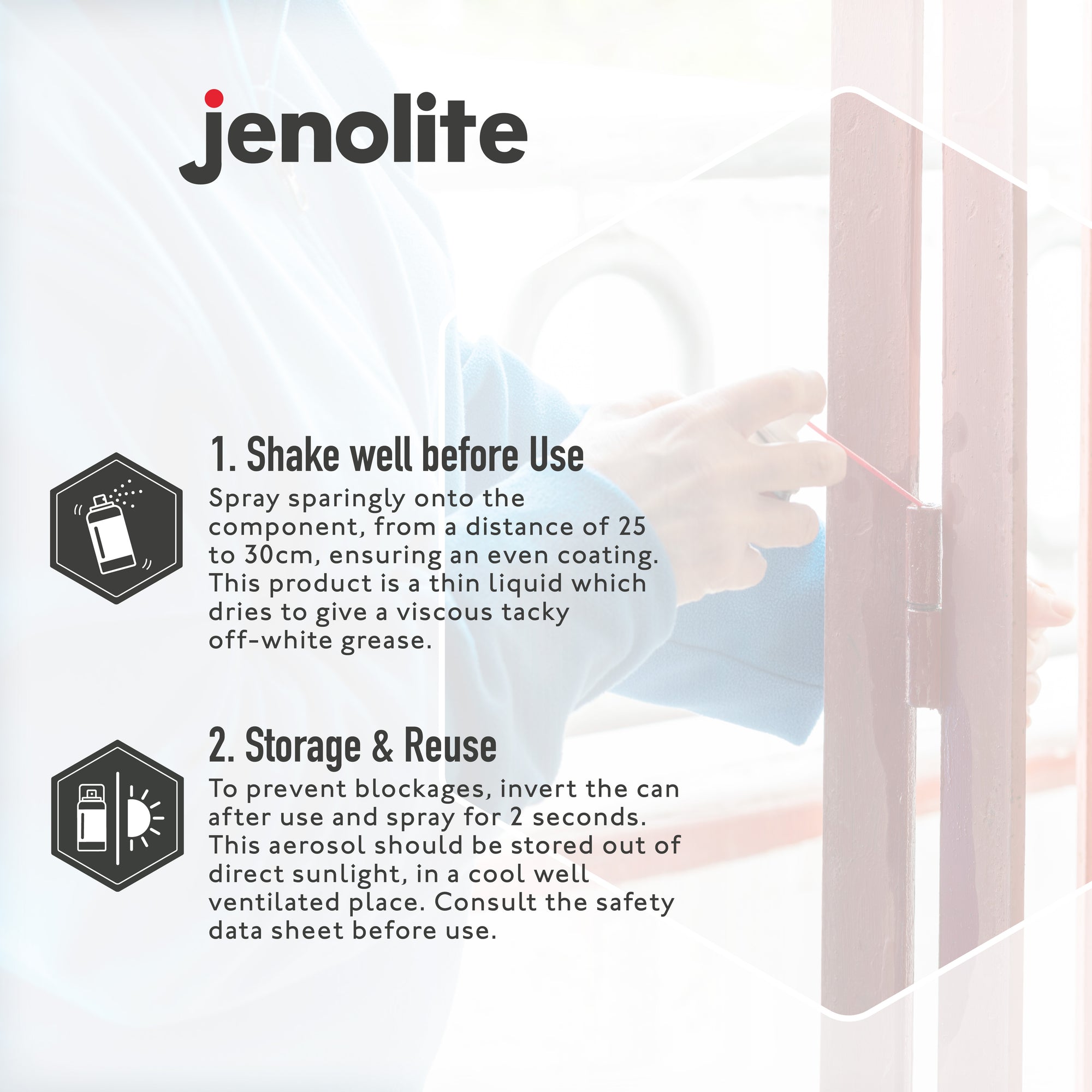

7. How do I apply the spray paint?

- Shake the can vigorously before use.

- Spray from 15–25 cm in smooth, even strokes to cover the surface.

- Apply multiple coats if needed for extra protection, ensuring a uniform layer.

8. Is it suitable for DIY use?

Yes. The 500ml aerosol format allows for easy, precise application, making it suitable for both DIY enthusiasts and professional mechanics.

9. Is it weatherproof?

Absolutely. The high-performance bitumen undercoat is water-resistant and weatherproof, protecting metal surfaces from rain, snow, and road salts year-round.

10. How should I store the product?

- Store in a cool, well-ventilated place, out of direct sunlight.

- After use, invert the can and depress the nozzle for 2–3 seconds to prevent blockages.

- Consult the Safety Data Sheet for additional handling and storage guidance.

11. Where is it made?

Made in Britain, ensuring high-quality rust protection and reliable performance.