Eiffel Tower - Case Study

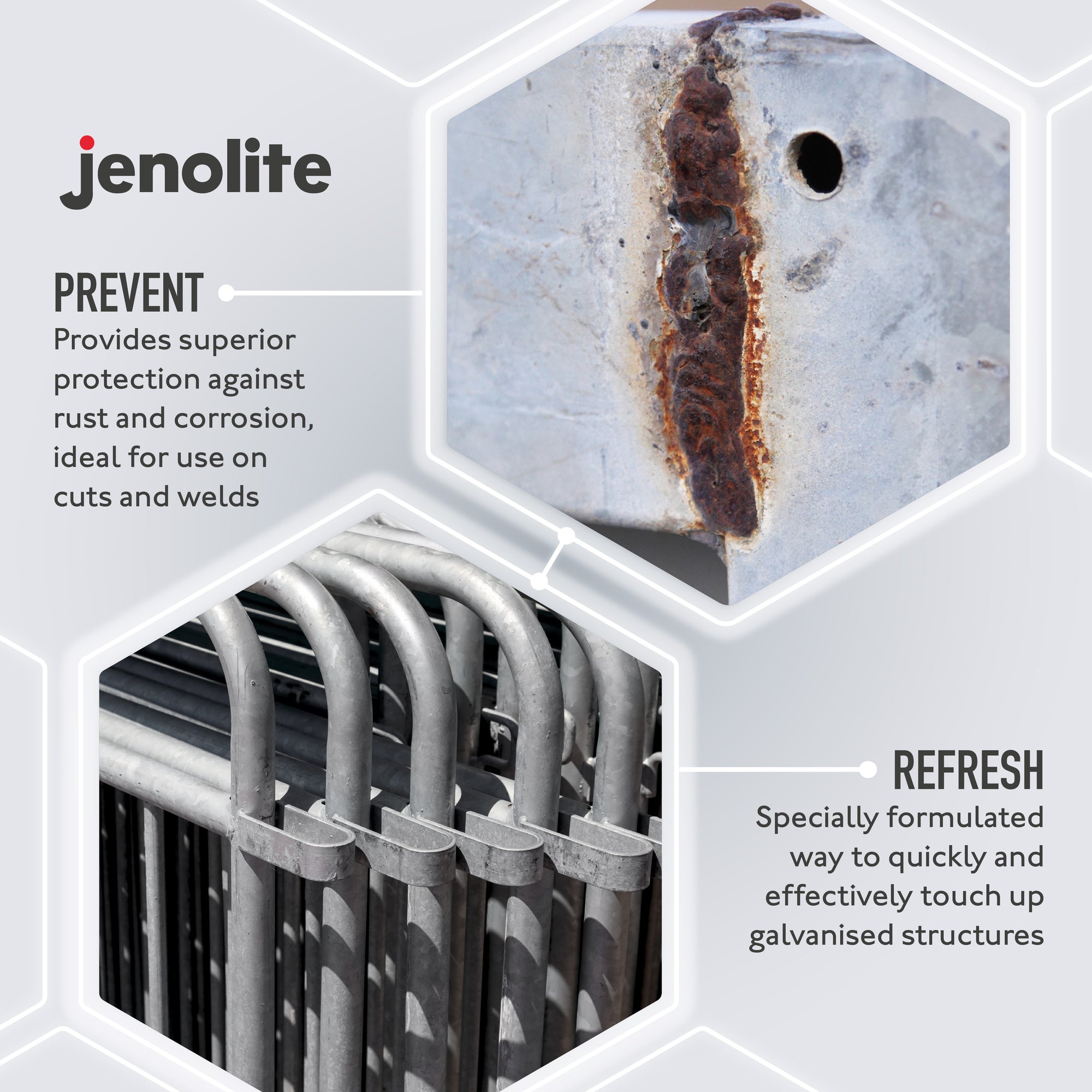

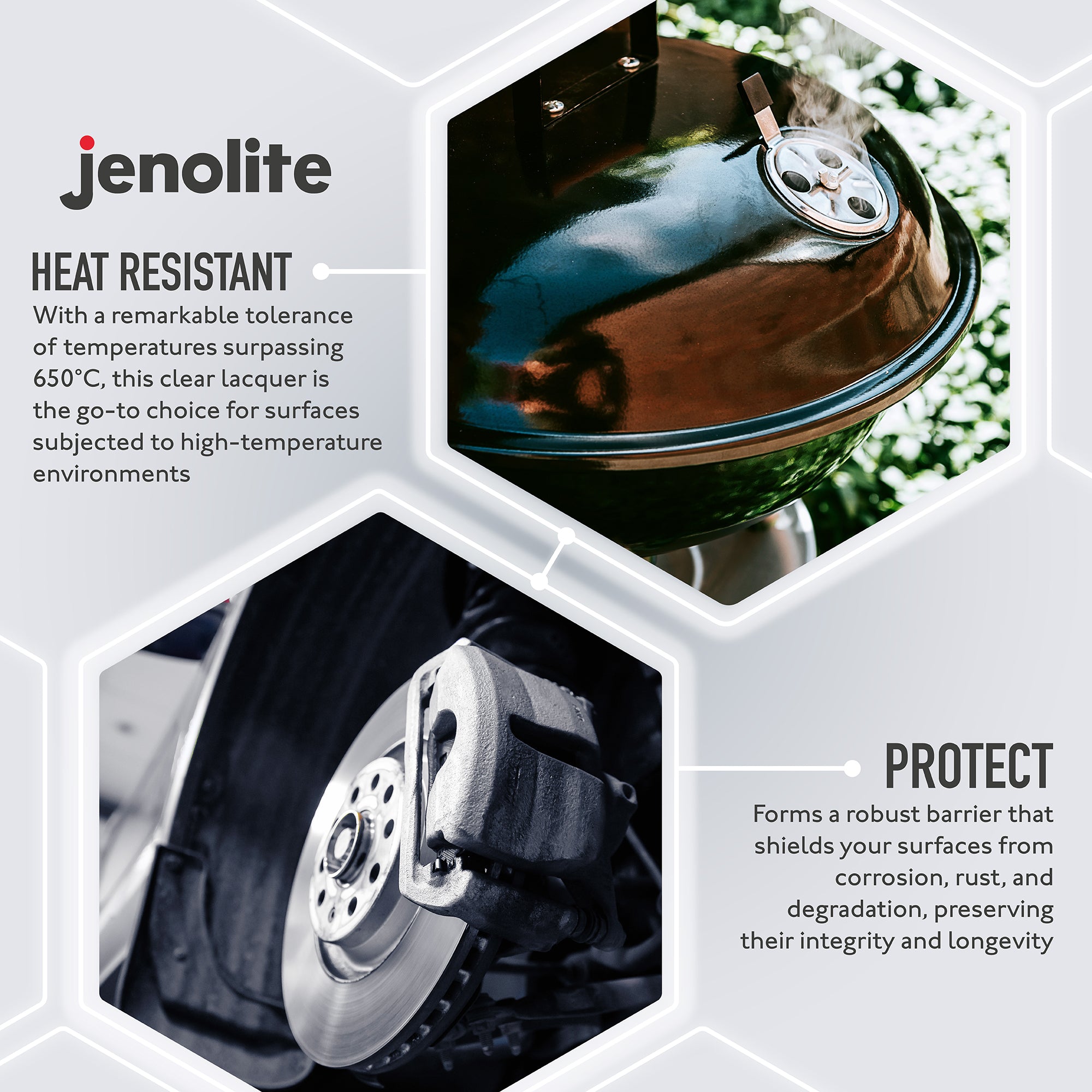

The manufacture, assembly and maintenance of steelwork, whether it be materials, plant, vehicles, bridges or buildings, require and efficient system of protection against corrosion is safety and long life are to be maintained.

Corrosion may come from within, through existing rust or mill scale; or from without, through moisture, acid fumes, sea air or other hostile influences in the atmosphere or environment.

Iron oxides (rust or scale) have a coefficient of linear expansion different from that of the underlying steel: thus temperature variations will unfailingly cause the separation of the oxide from the metallic surface and the breakdown of any paint coatings applied.

In spite of the protective finish, moisture, air from the sea or acid fumes will infiltrate through joints, rivet heads or through the impact damage. Such corrosive influences will reach the basis metal, where its oxide and the naturally porous rust will retain any moisture and will create a difference of potential between metal and oxide. The electrolyte thus formed will constitute an electric cell which creates and releases oxide and damages the metal.

It is necessary, therefore, during the erection of steelwork or during its renovation, to eliminate rust and scale while ensuring that the metal surfaces are passivated prior to painting. Processes employing powerful mineral acids, such as hydrochloric or sulphuric solutions, liberate soluble ferrous salts; yet they are in themselves highly corrosive and treated surfaces remain ‘active’ and ready to form new oxides. Similarly, sand or shot blasting leave an active surface upon which oxidation occurs immediately.

Treatment of steelwork with Jenolite RRN is by contrast successful since this process not only removes all the products of corrosion but also passivates the surface and affords lasting protection against re-rusting.

Well known fact

It is well known, that orthophosphoric acid, which forms the basis of RRN, transforms iron oxide into a non-reactive, non-conductive and insoluble phosphate coating. To this acid are added specially developed inhibitory products which limit the acid attack and activate the surface and ensure the following:-

- Complete wetting of the surface;

- Permeation of the process through the pores and cavities to the metal;

- Removal of the oxide and its replacement by a film of iron phosphate which is incorporated with the metal. This acts as an insulator and eliminates electrolytic action by preventing the passage of current between poles. Thus, formation of further oxide is inhibited.

- Maximum paint adhesion and, therefore a considerable increase in the life of protective finishes.

Justification of this principle of rust removal and prevention is of course to be found on installations of every kind throughout the world. In April, 1955, Jenolite products were used in a number of rust removal experiments carried out on the Eiffel Tower. This famous structure, a network of steel, is to many people the landmark of Paris and details of these anti-corrosion tests will be widespread interest.

The subject of the tests are 24 risers of a new staircase on the west side of the tower at the fifth flight from ground level. The treads of this section of the staircase were not jenolized; they were merely painted with red lead and will be available as such for purposes of comparison. Before treatment, the risers were rough finished and covered with scale and rust. Only the inaccessible rear sections were coated with read lead paint.

The Jenolite process was applied as follows to the front face risers, starting from the fourth flight landing:-

- The first eleven risers (including a 5cm-wdie strip on the fourth flight landing next to the first riser) were treated with liquid Jenolite RRN, applied by wire brush in accordance with Jenolite instructions. The treatment took about ¼ hour to complete and entailed the use of approximately 250 cc of solution. Two hours later a coating of grey Chemical Sealer (CS 1) was applied by brush. This preparation, developed expressly as a supplement to RRN, combines with the tacky residual solution left on the metal surface after processing with the latter. The combined treatment affords a strong, rust inhibitive foundation keyed for paint. Chemical Sealer may be painted over in approximately four hours.

- The next ten risers received an application of Jenolite RRN paste applied by brush. Two hours after application the paste was removed with a spatula and a hard wire brush was used n the steel surfaces. As an experiment, eight of these risers (numbers 14 to 21) were given a coating of Jenolite RRN solution, applied by brush. Immediately afterwards, all ten risers received a coating of Chemical Sealer (CS 1).

- The last three risers (numbers 22, 23 and 24) were not in position. With the approval of D. Barker (Chief Engineer, of the Technical Service of the Eiffel Tower Company), M. H. Rabate (Consultant Engineer), and M. Lovenfosse (Engineer with Ets. Eiffel Metallic Constructions), it was decided to process these three risers at the Jenolite works under similar conditions as in the factory before assembly. The risers were immersed for 20 minutes in a Jenolite RRN processing tank. The solution was diluted at 1:4 with water and heated to a temperature of 70 degrees Celsius. After quick air-drying (time: 30 minutes) these three risers received, on both faces, two coats of Jenolite Chemical Sealer (CS 1). The coatings were applied at an interval of one hour.

Following processing, the risers were delivered to the Eiffel Tower and were permanently mounted two days after the treatment of the previous risers.

The possibilities of more widespread pre-treatment with Jenolite products is now being investigated. The process will be applied to test samples of flat or bent sheets which will be exposed to weather after being placed in selected positions on the Tower.

The Jenolite range of processes includes paint strippers, degreasers, scale removers, aluminium treatments applicable in all operations necessary for the pre-treatment of metals. Jenolite Technical Service is available throughout the world to all those interested in combating corrosion and increasing the life of their metalwork.