We've observed a rise in inquiries from concerned building managers regarding the recent announcement by the Health and Safety Executive: 'RAAC is now life-expired and is liable to collapse with little or no notice.'

With the new school year approaching, questions persist about schools and public sector buildings that contain RAAC. With the start of the new school year upon us, questions persist about the safety of schools and public sector buildings affected by the presence of RAAC.

What is RAAC/AAC?

RAAC, a specific form of precast AAC produced primarily from the 1950s to the 1980s, offers lightweight closed-cell components. It consists mainly of AAC plank material with embedded longitudinal and transverse steel reinforcement to provide flexural and tensile strength. AAC is characterised by a high void content, susceptibility to moisture, and potential for carbonation, does not naturally protect embedded steel reinforcement from corrosion. Consequently, AAC structures rely on external coating systems to shield and prevent corrosion of the embedded steel. These coatings act as a barrier, safeguarding the reinforcement from environmental factors. Even today, precast AAC masonry blocks remain popular in construction across various regions, including Europe, the Middle East, and Asia. RAAC, or Reinforced Autoclaved Aerated Concrete (RAAC), was extensively used in the construction of precast planks, flat roofs, and walls in public sector buildings.

What is the relationship between RAAC and corrosion?

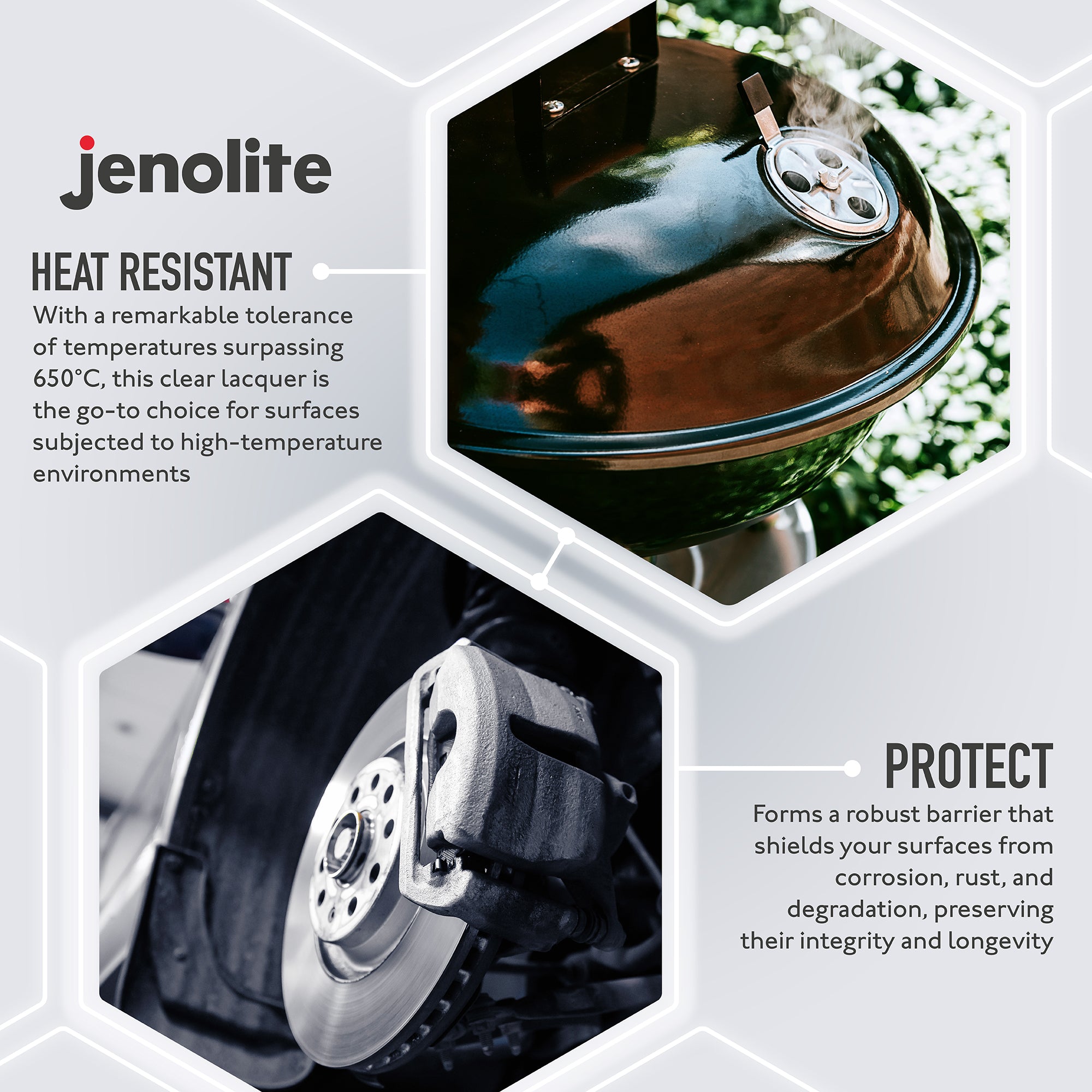

The relationship between RAAC and corrosion is notable due to the steel reinforcement used in RAAC structures. RAAC incorporates steel bars or mesh for structural strength. Steel corrodes when exposed to moisture and oxygen. In reinforced RAAC structures, inadequately protected steel reinforcement will corrode and rust over time. This rusting weakens the structural integrity of RAAC elements and jeopardises overall construction stability.

How to prevent corrosion issues with RAAC?

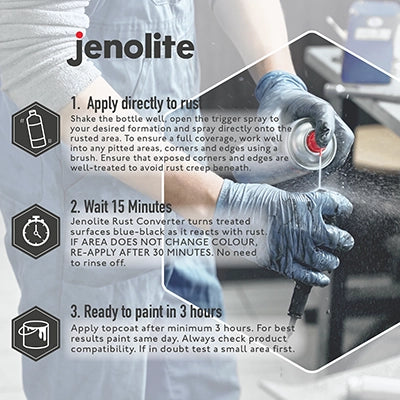

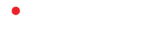

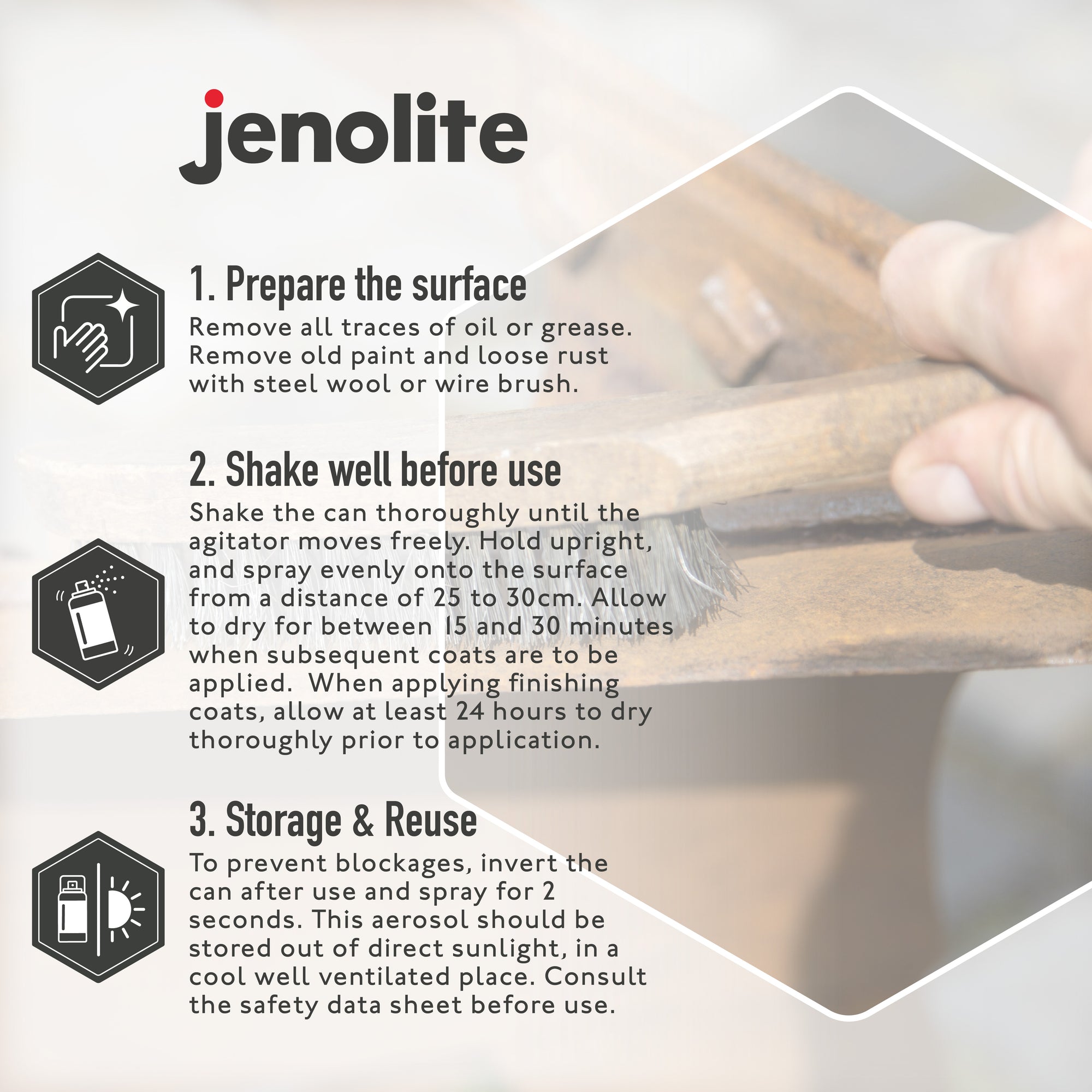

To mitigate corrosion-related issues in RAAC structures, and as a fundamental construction best practice, it's imperative to ensure proper protection for steel reinforcements. This involves the application of protective coatings or treatments to safeguard the steel. Additionally, sound construction practices, such as ensuring proper drainage and sealing joints and connections, are essential for the long-term safety and durability of construction.

We extend our best wishes to all involved in addressing these substantial challenges.

![Rust Remover vs Rust Converter: Which To Use? | [UPDATE 2024] A comprehensive guide](http://www.jenolite.com/cdn/shop/articles/Rust_Remover___Converter.webp?v=1706616225&width=2000)