Rust, a common issue for iron and its alloys, results from the chemical reaction between metal and environmental elements, leading to corrosion. Addressing this problem effectively requires understanding the distinct solutions available: Rust Converters and Rust Removers.

This guide offers a concise overview of both treatments, exploring their mechanisms, applications, and considerations. Whether dealing with a corroded garden gate or a rusted piece of machinery, selecting the appropriate method is crucial for restoration and protection. Join us as we demystify these rust treatment options, empowering you with the knowledge to preserve and rejuvenate your metal assets.

What is Rust?

Rust is a form of corrosion that occurs when iron or its alloys, such as steel, are exposed to oxygen and moisture over time. This chemical reaction, known as oxidation, leads to the formation of iron oxide, a reddish-brown compound commonly referred to as rust. Rust weakens the affected metal, causing it to degrade and eventually crumble if left untreated. It is a common issue in metal objects and structures, particularly those exposed to outdoor elements.

What is Rust Converter and what does it do?

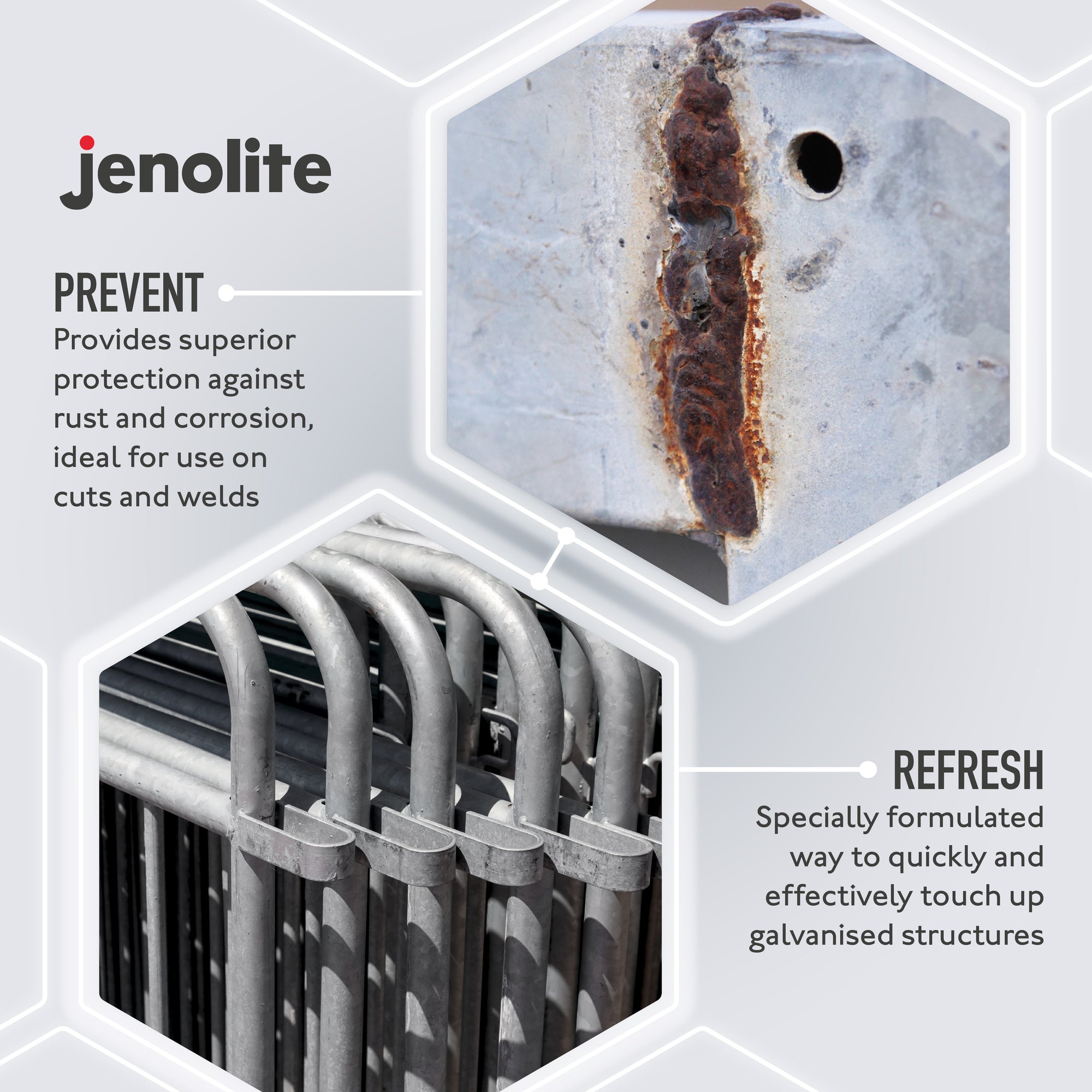

Rust converters are chemical solutions used to treat rusted metal surfaces by chemically converting iron oxide (rust) into a more stable compound. Typically containing active ingredients like phosphoric acid or tannic acid, these solutions react with the rust, forming a protective barrier that prevents further oxidation.

Here's how they work:

- Upon application to the rusted surface, the rust converter chemically reacts with the iron oxide, breaking it down into a stable compound.

- This reaction transforms the rust into a black, inert substance, often referred to as a primer.

- The converted surface can then be painted over or coated with a protective layer to seal and prevent future rusting.

- Rust converters effectively halt the progression of rust and provide a stable foundation for additional treatments or finishes.

Overall, rust converters offer a convenient and efficient solution for restoring and protecting metal surfaces affected by corrosion, extending the lifespan of the metal and preserving its appearance.

What can I use Rust Converter on?

Rust Converters are suitable for use on any ferrous metals, iron or steel object such as a rusted cars, vans and bikes, trailers, fences, gates, iron railings, staircases, sheet metal, cast iron ornaments, the outsides of water tanks, lawn mowers, boats, farm equipment, etc. They are not suitable for use on aluminium, copper, stainless steel or galvanised metal.

What to do before using Rust Converter?

Before using Rust Converter, ensure the surface is free from grease, oil and dirt, as this can interfere with the chemical reaction. Use a wire brush or sander to remove any loose rust and paintwork, this will help the converter penetrate deeply into the rust. Do not remove all rust, as rust must be present for the process of conversion to begin. Rust Converters chemically bond to the rust in order to seal it in, therefore Rust Converter should only be applied to rusted areas.

Typical common mistake are:

1) Applying converter too thickly, which slows the process and stops the area from drying.

2) Applying to surfaces free from rust. Rust must be present in order for the chemical reaction to to be triggered. Without that the converter will simply dry white.

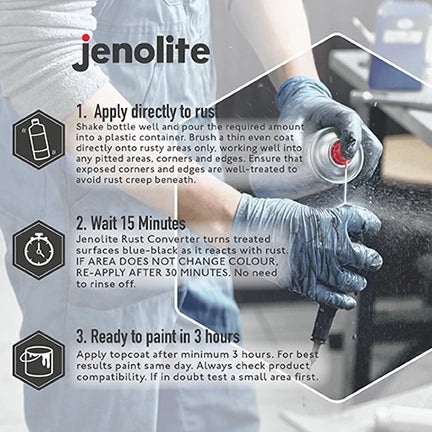

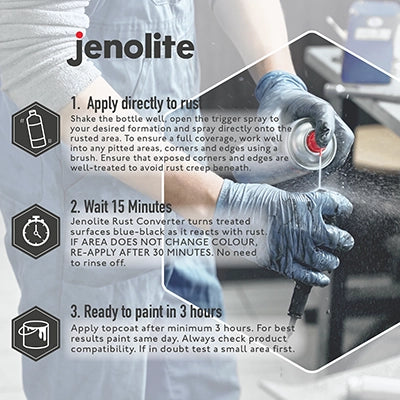

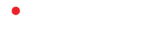

The Jenolite Rust Converter range is fast acting, simple to use and includes:

-

Rust Converter Liquid, a water based product which can be applied using a brush or trigger spray

-

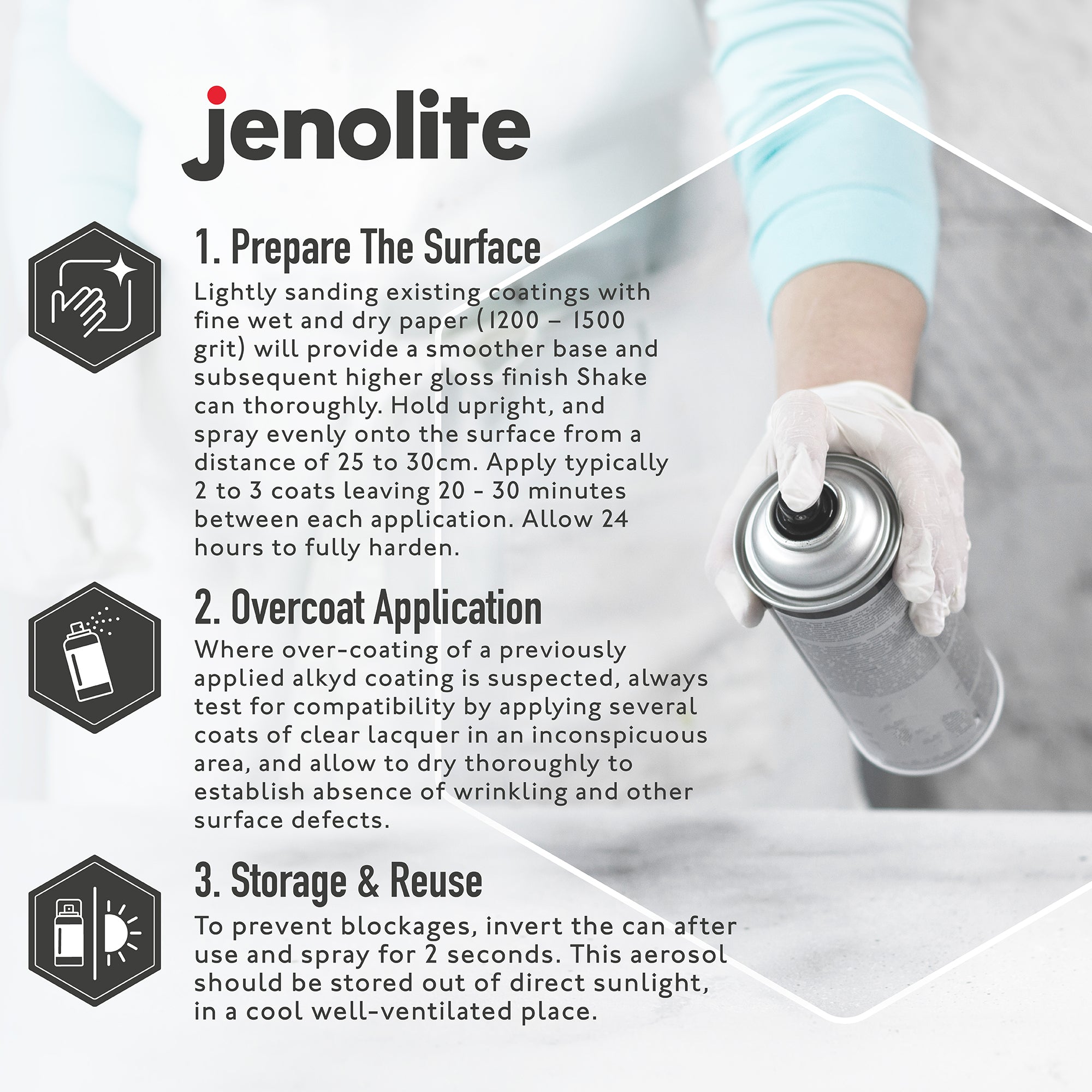

Rust Converter Aerosol Spray, an epoxy based product that is applied by aerosol

How long does it take rust converter to work?

Once applied, making sure all areas of rust are covered, wait approximately 15 minutes, after which you should see the rust starting to turn into a blue-black colour. If it doesn’t change colour then reapply after 30 minutes. Make sure to apply rust converter in thin coats, rather than thick layers. If you are using the rust converter spray, apply 2 or 3 light coats with 15 minute intervals. Wipe away converter that may have splashed on to paintwork, etc to avoid staining. After use wash all equipment used with clean water.

Leave the area for 3 to 24 hours (dependent on the ambient temperature ) to fully cure before painting.

Pros of rust converter

-

Rust converter is easy to use, and fast acting, requiring little manual work before and after application.

-

Rust converter encapsulates rust and leaves a strong barrier that is resistant to water vapour and oxygen, preventing the reappearance of rust. It is also resistant to chemicals and salt spray which makes it perfect for protecting against the elements. Ideal for cars and other vehicles.

Cons of rust converter

-

Failure to prepare the surface properly can may result in incomplete rust conversion and compromised adhesion of subsequent coatings

-

Rust converter is best used on light rust. On heavily rusted areas, it may not fully penetrate the rust, only treating the top layers.

-

Converting rust does not allow you to fully inspect the integrity of the metal surface, which can mask areas of weakness. In areas that require the surface to be structurally sound, we always recommend using a rust remover, to strip away rust back to bare metal (car chassis, etc)

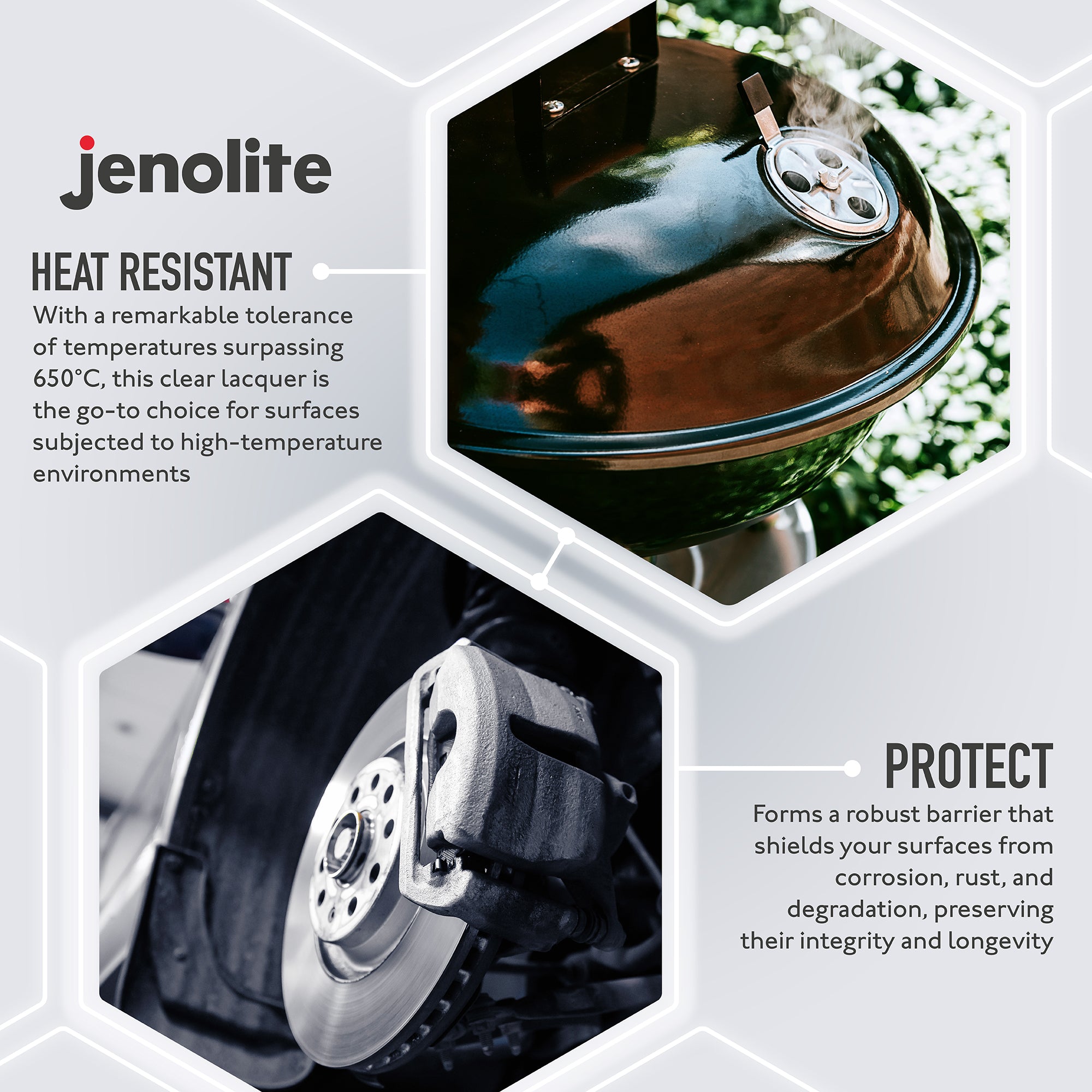

- Rust converter is not suitable for use on surfaces that are exposed to high temperatures or the inside of fuel tanks.

What is Rust Remover and what does it do?

Rust remover is a chemical solution formulated to dissolve and eliminate rust from metal surfaces. It works by breaking down the iron oxide (rust) through a chemical reaction, making it easier to wipe or wash away. Rust removers come in various forms such as liquids, gels, or sprays, and they are applied directly to the rusted area. They effectively restore metal surfaces by removing rust and preparing them for further treatment or coating, helping to extend the lifespan of the metal.

What can I use Rust Removers on?

Rust removers are designed to work on ferrous metals, which are metals that contain iron. This includes metals such as:

- Steel

- Cast iron

- Wrought iron

Most Rust Removers are not suitable for use on non-ferrous metals (those that do not contain iron / steel), such as aluminium, copper, brass, or bronze. When looking to treat these metals, it is important to use specialised rust removers. Always check the instructions or consult with the manufacturer to ensure the rust remover is safe for use on the specific metal you're dealing with.

They are great for treating rust on vehicles, lawnmowers, bikes, boats, machinery, railings, gates, garden furniture, tools, etc.

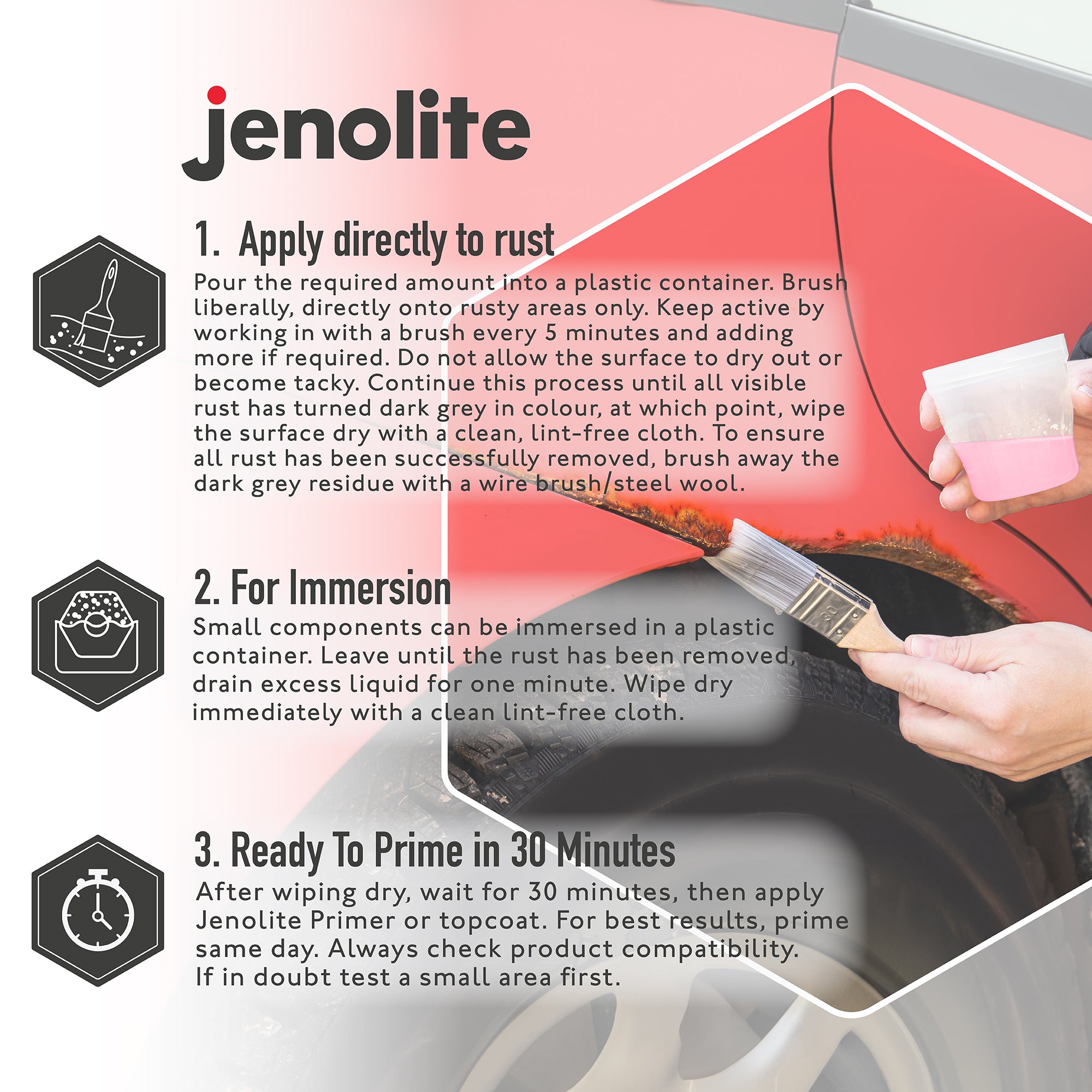

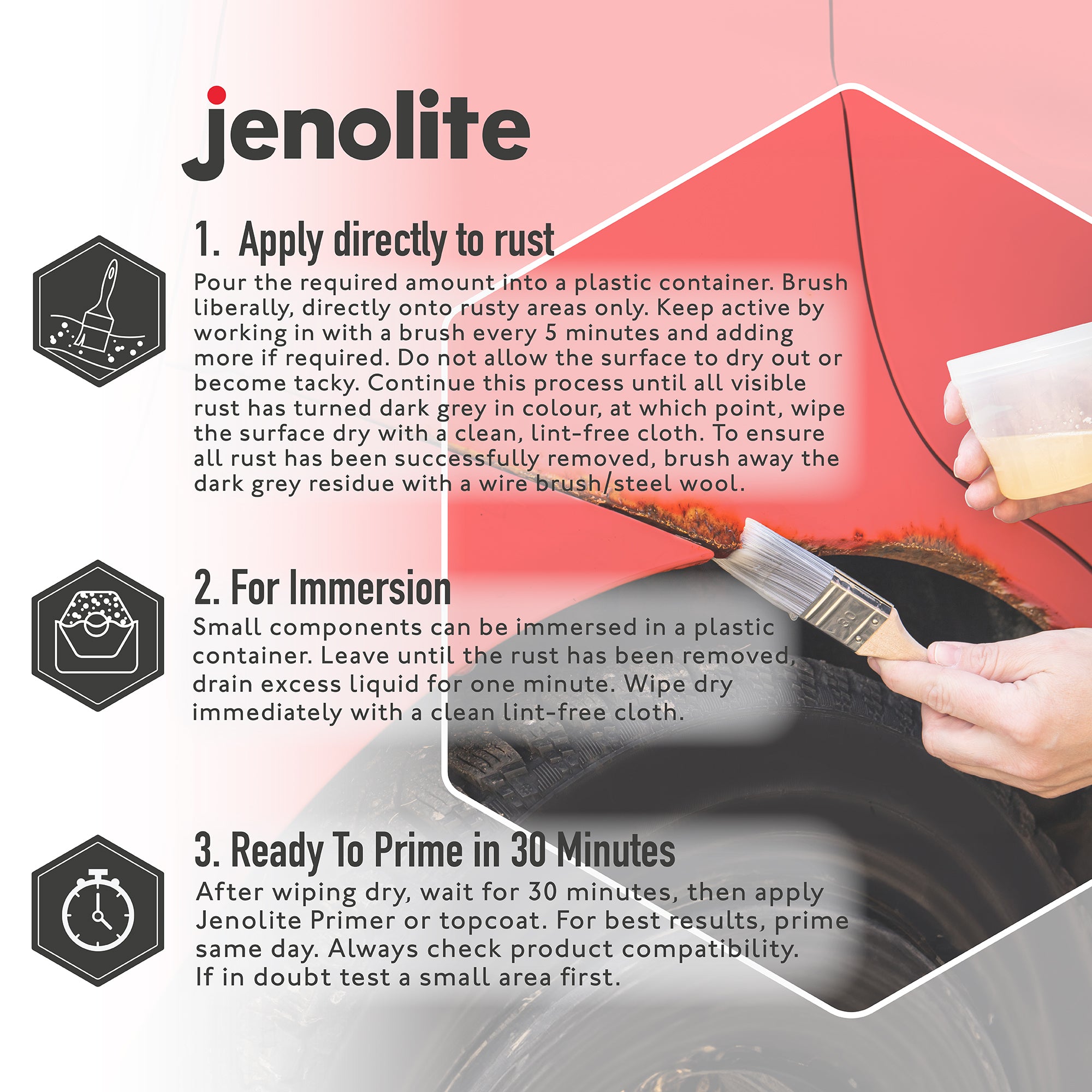

The Jenolite Rust Remover range is fast acting, simple to use and includes:

-

Rust Remover Gel, a concentrated, non-drip formula, that stays where applied, so is ideal for vertical surfaces and precision application. Applied with a brush.

-

Rust Remover Thick Liquid, a thick solution that is non drip will cling to surfaces. Ideal for vertical surfaces, where larger areas are being treated. Applied with a brush.

-

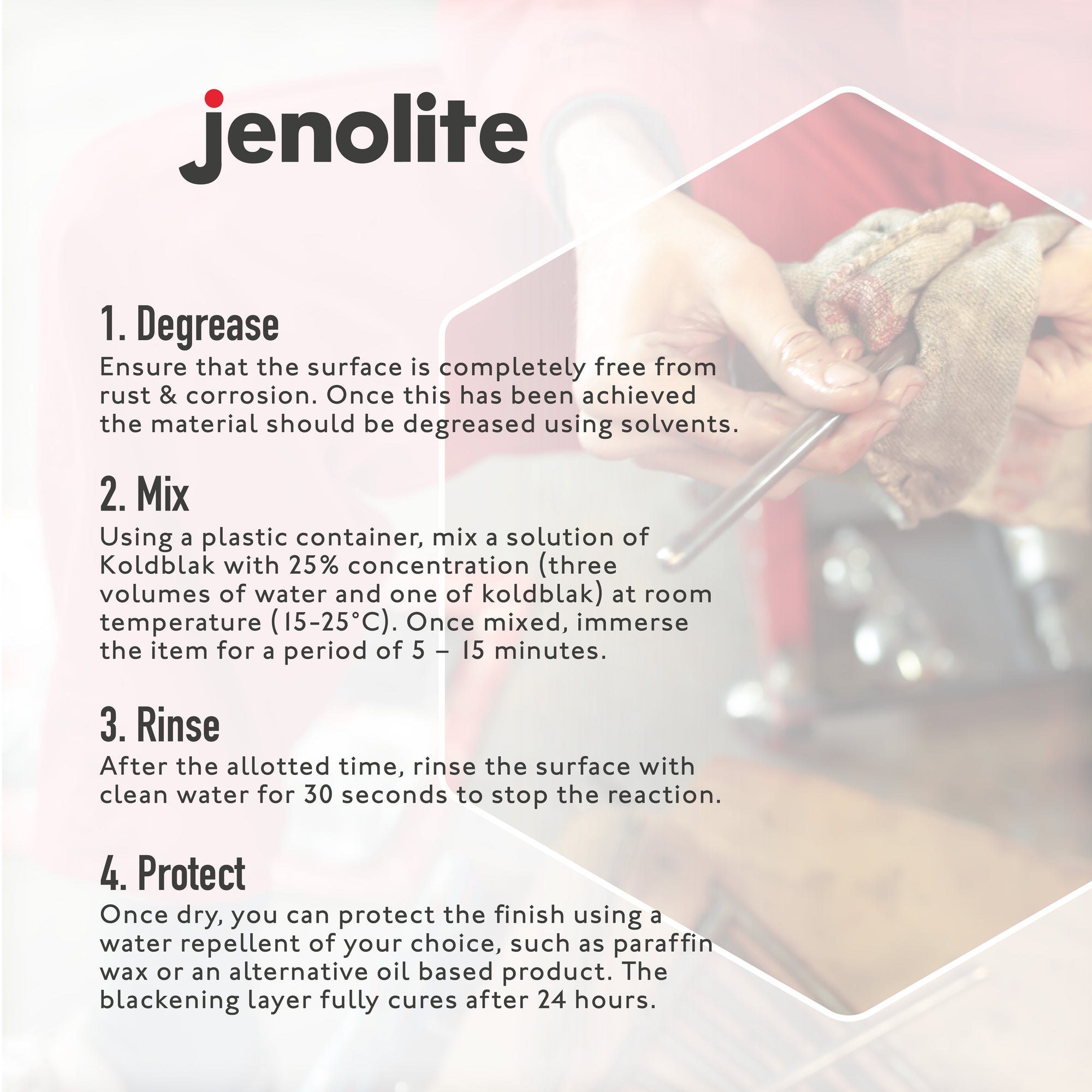

Rust Remover Liquid, a thin liquid solution, can be used to immerse rusted items in. Great for use on smaller items, such as tools, nuts, bolts, etc. It can also be applied by use of a trigger spray.

-

Non-Hazardous Rust Remover, is water based rust remover, for use with ferrous and non-ferrous metals. Is best used by immersing the item into the solution and leaving to work. This can take several hours depending on the level of rust.

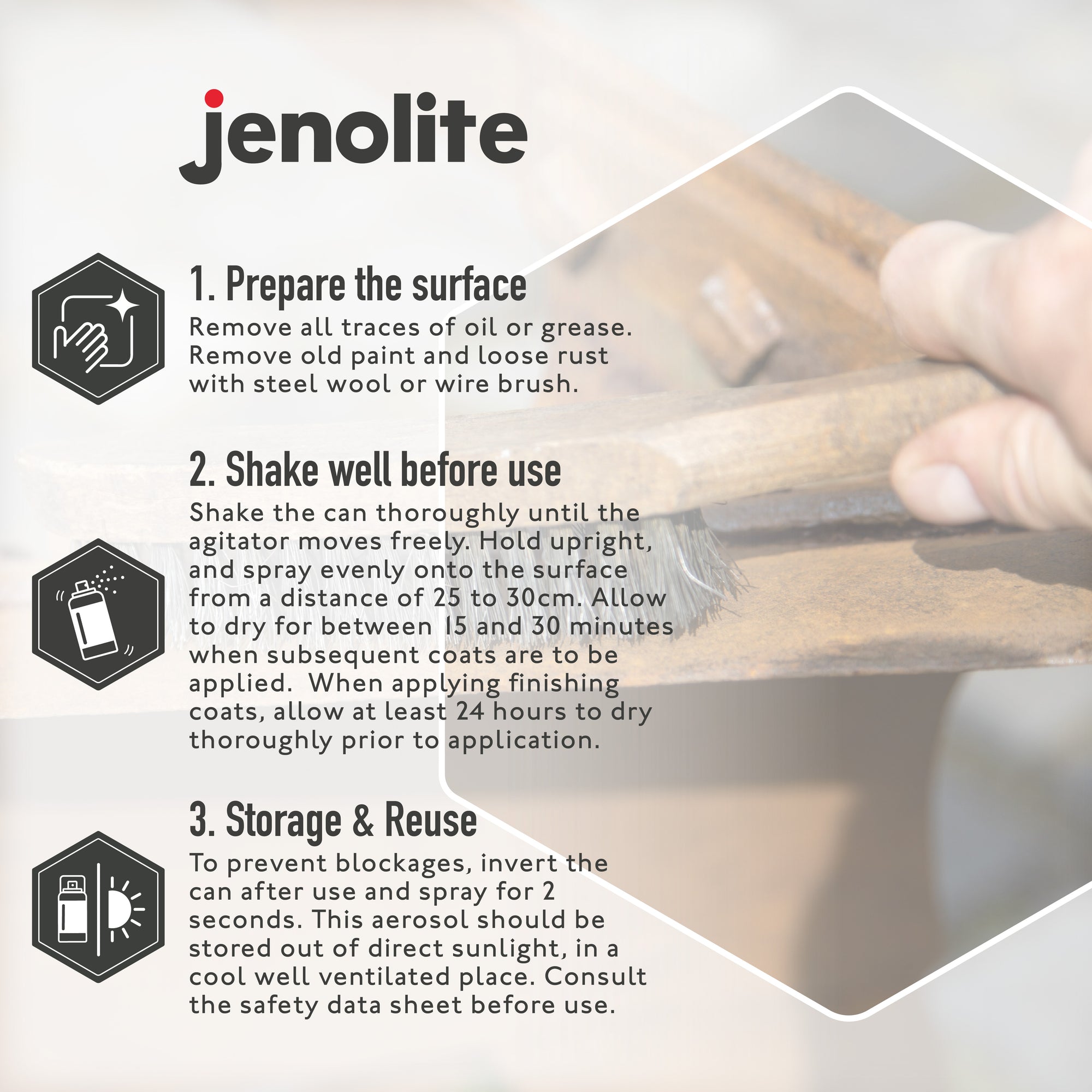

What to do before using Rust Remover?

Before using a rust remover, it's important to prepare the surface and take certain precautions to ensure effective and safe usage.

- Clean the Surface: Remove any loose rust, paint and debris, using a wire brush, or sander. Clean away any dirt or grease from the surface of the metal using soapy water. This helps to ensures that the rust remover can penetrate the rust effectively.

- Protect Surrounding Areas: If possible, remove the metal object from areas where contact with other materials could cause damage. If it is not possible to remove it, cover the surrounding surfaces with plastic or other protective materials to prevent accidental spills or splashes. Rust remover can stains paint work and damage plastics.

- Wear Protective Gear: Wear gloves and safety goggles to protect your skin and eyes from contact with the rust remover solution. Some rust removers can contain harsh chemicals, so taking proper precautions is essential.

- Ventilation: Work in a well-ventilated area to minimise exposure to fumes from the rust remover. If working indoors, consider opening windows or using a fan to improve airflow.

- Read Instructions: Carefully read and follow the instructions provided by the manufacturer of the rust remover. Different products may have specific application methods and safety guidelines that you need to adhere to for best results.

By following these steps, you can prepare the surface and ensure a safe and effective application of the rust remover to remove rust from your metal objects.

How long does it take rust remover to work?

The effectiveness of rust remover and the time it takes to work can vary depending on factors such as the product used, the severity of the rust, and the type of metal being treated. Generally, you will start to see visible results within a few minutes, or several hours after application.

Typically when using Rust Remover you will see it begin to work after 5 minutes. After approximately 15-10 mins, you can use a wire brush keep the solution active and help it penetrate the rust. As it begins to work, the rust will begin to turn a dark grey to black colour. A handy tip is to not let the rust dry out. If it does, you can apply more rust remover to reactivate it.

After 15-30 mins (dependent on severity of the rust), use a dry cloth or water to remover the Rust Remover and inspect the area. If rust is still present, repeat the process. Any black residue can be removed with a wire brush.

If you are immersing smaller objects, you can leave the components to soak and wipe away with a lint-free cloth once you can see the rust has come off.

Pros of Rust Remover

- Effectiveness: Rust removers are specifically formulated to dissolve and remove rust from metal surfaces, making them highly effective at restoring the appearance and functionality of rusted items.

- Convenience: Rust removers are easy to apply and typically require minimal effort to use, especially when compared to manual methods like sanding or wire brushing.

- Versatility: Rust removers can be used on a variety of metal surfaces, including steel, cast iron, and wrought iron, making them versatile for different applications.

- Long Term Solution: Once all rust has been removed, the surface is ready for treating and sealing, to provide long term rust protection.

- Inspection of the surface: By removing all the rust, you can check the quality and strength of the surface, essential in areas of structural integrity, such as car chassis.

Cons of rust remover

- Chemical Hazards: Many rust removers contain harsh chemicals that can be harmful if not handled properly. Users should take precautions such as wearing gloves and protective eyewear to minimise exposure. (This excludes Jenolite's Non-Hazardous Rust Remover, which is a water based product)

- Surface Damage: Some rust removers may cause damage to the underlying metal surface if left on for too long or used incorrectly It's essential to follow the manufacturer's instructions and test the product on a small, inconspicuous area first and avoid it coming into contact with other materials.

- Rust Removers typically require more effort and time to completely remove rust, as they involve scrubbing or brushing the surface to remove the rust.

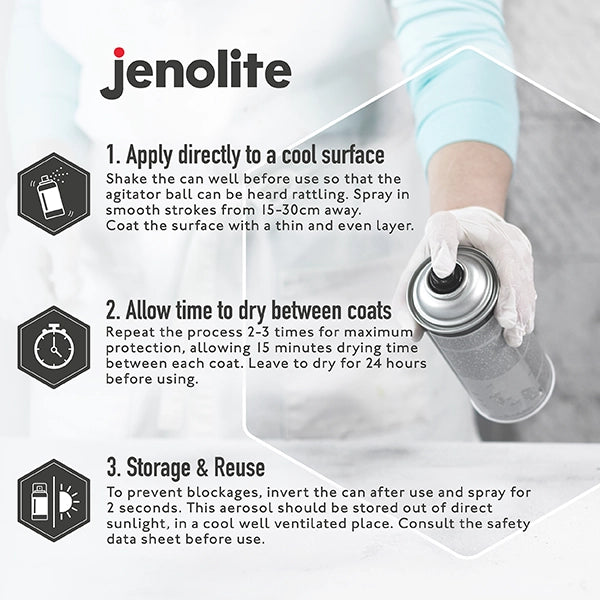

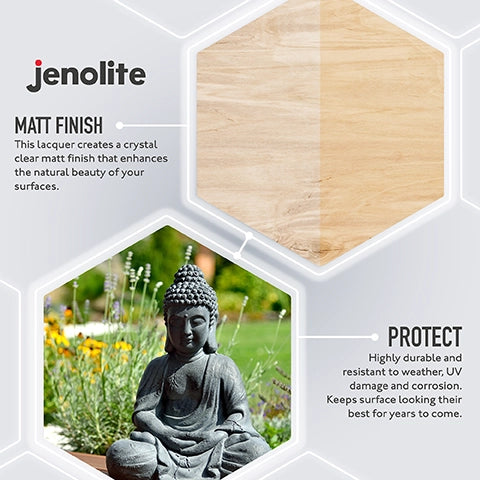

- Requires application of surface protection: Bare metal can begin to rust extremely quickly. Flash rust can appear in 24hrs after treatment, so it is important that once rust has been removed, exposing the bare metal, that the surface is protected and sealed as soon as possible, either with primers and paints, metal lacquers or similar metal protection coatings. Jenolite has a wide selection of anti-rust primers and paints, as well as metal surface protector lacquers, including Jenolite Rust Shield Aerosol.

Conclusion

Choosing between using a rust remover or a rust converter depends on several factors, including the extent of rust on the metal surface, the type of metal, the location of the rust and your preferences regarding the final appearance and long term protection of the metal.

Extent of Rust:

Rust Remover: If the metal surface is heavily rusted or if you want to completely remove the rust to reveal bare metal, a rust remover is typically the better choice. Rust removers dissolve and remove existing rust, leaving the surface clean and ready for further treatment.

Rust Converter: If the rust is minor or you prefer to convert the rust into a stable, protective coating, a rust converter is a suitable option. Rust converters chemically react with the rust to convert it into a stable compound, preventing further corrosion.

Type of Metal

Rust Remover: Rust removers are generally safe to use on ferrous metals (those containing iron), such as steel, cast iron, and wrought iron.

Rust Converter: Rust converters are suitable for use on ferrous metals as well, but they can also be used on non-ferrous metals like aluminium, providing a protective coating without removing the rust.

Ease of Use and Convenience:

Rust Remover: Rust removers typically require more effort and time to completely remove rust, as they involve scrubbing or brushing the surface to remove the rust.

Rust Converter: Rust converters are generally easier and quicker to use, as they chemically react with the rust to convert it into a stable compound without the need for extensive scrubbing or brushing.

Consider these factors carefully to determine whether a rust remover or a rust converter is the best option for your specific rust removal and metal protection needs.

If you have any further questions on rust or protecting your metal, click the WhatsApp icon on the right to send us a message, give us a call at 01234924794, or send us an email using the contact form.

![Rust Remover vs Rust Converter: Which To Use? | [UPDATE 2024] A comprehensive guide](http://www.jenolite.com/cdn/shop/articles/Rust_Remover___Converter.webp?v=1706616225&width=2000)