Wire Brush

Steel wire brush. Perfect for removing loose and stubborn rust. Essential use prior to using remover or converter products.

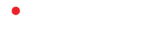

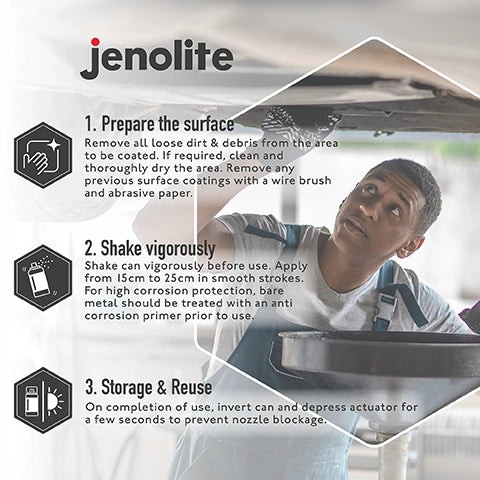

Surface Preparation:

- All traces of oil and grease must be removed with a suitable degreaser.

- Remove any loose or heavy rust by wire brushing or other abrasives. Brush away any fine rust deposits after abrasion.

- Apply the selected rust remover. Extra coatings of rust remover may be required if the surface is heavily rusted. If rust removal is incomplete, reapply the liquid after 10 minutes, thixotropic after 20 minutes and paste after 1 hour. Agitation of the rust remover with a brush will assist reaction.

- When all the rust has been removed a grey surface is formed. Wipe the surface dry with a clean lint free cloth while the product is still wet on the surface.

- Do not allow the product to dry on the surface without wiping. This leaves a surface that ensures good adhesion for paint.

- Following treatment the surface should be painted or protected with oil within one hour.

- Jenolite Liquid can be used to remove the light oxide films that are produced after shot blasting or grit blasting. Apply to the surface for 2 to 3 minutes and immediately wipe dry while still wet.

- Jenolite Liquid can be used to derust components by immersion. A polythene tank can be used for immersion at ambient temperature. The degreased components are immersed in Jenolite Liquid, used as supplied until all the rust has been removed. The products are wiped dry immediately after immersion.

- Good quality primers are recommended. It is not recommended that etch primers or Zinc Rich primers are used. If body fillers are used on Jenolite treated surfaces it is essential that all chemicals have been wiped away. If in doubt, wipe the Jenolite treated surface with a cloth and warm water and dry immediately. Check the compatibility of all products that are to be used after derusting.

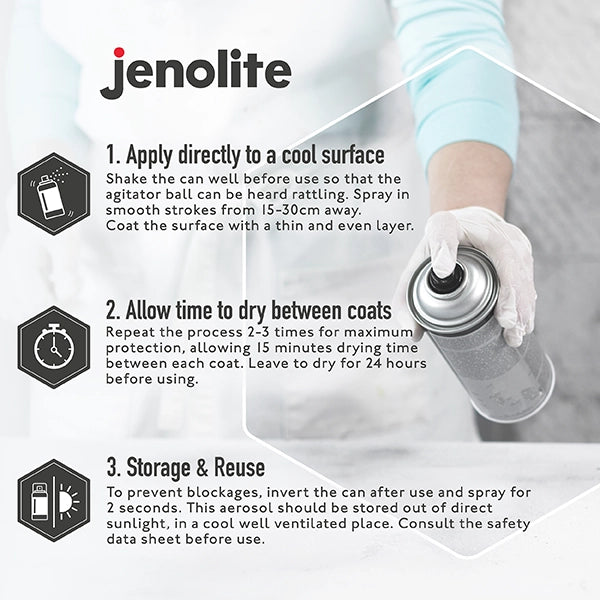

- Primers must also be compatible with top coats. When using epoxy paints or two packs it is advisable to use the products as for body fillers. When using Jenolite Rust Removers it is important that the metal surface treated is between 15 – 25 deg.c. Lower temperatures will increase derusting times. Extremely slow below 10 deg.c. For immersion in the liquid, the temperature of the liquid can be increased above 25 deg.c. to improve the derusting power. Metal surface temperatures above 25 deg.c. can result in the rust remover drying out prematurely leaving a black glazed coating. If this occurs, cool the surface by washing with water, abrade the surface to remove the black coating and reapply rust remover.

- Any spillage or rust remover on sound painted surfaces not being refurbished should be washed off immediately with water. If white deposits appear on the derusted surface within one hour of drying it is due to humidity. Re-apply the rust remover for five minutes and immediately wipe dry.

- None of the products will affect stainless steel, but are very effective in removing surface rust and blue scale from welded areas. After removal of the scale, rinse with water and dry the surface.

- If creep corrosion is apparent from a rusty area on a painted surface, then the surrounding paint must be removed to remove all rust and treated accordingly. If nylon or acrylic etc. type components are attached to the rusty steel parts, avoid contact rust remover with the plastic as stress cracking of the plastic material could occur. Wash off any contact immediately with water.

- Jenolite Rust Removers can be used for the treatment of non ferrous metals for removing oxide and tarnish films. Always rinse with water and dry after treatment.

![Rust Remover vs Rust Converter: Which To Use? | [UPDATE 2024] A comprehensive guide](http://www.jenolite.com/cdn/shop/articles/Rust_Remover___Converter.webp?v=1706616225&width=2000)

Rust Converters chemically transform rust into a protective layer, stopping corrosion and preparing the surface for further treatment. Rust Removers, in contrast, directly dissolve rust, returning metal to its pristine...